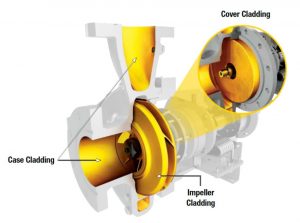

Protect Your Rotating Equipment with Conforma Clad

Refineries process some of the world’s most aggressive fluids and slurries. In these harsh environments, pump life can be severely limited by extreme erosive and corrosive wear, leading to increased maintenance costs, reduced reliability, and increased downtime.

What We Offer:

- Tungsten carbide protecting all wetted pump surfaces

- Final finishing of cladding to achieve dimensional requirements

- Collaboration with pump OEM to meet required specifications

- Longer pump life & increased mean time between repair/failure (MTBR/MTBF)

Applications Include:

- Bottoms Pumps

- Residual Oil Pumps

- Coke Drum Charge Pumps

- Coke Pit Pumps

- FCC Charge Pumps

- Slurry Pumps

Conforma Clad can also be applied to shaft sleeves

Pump Configurations:

- Overhung API Pumps

- Between Bearing API Pumps

- Custom Configurations

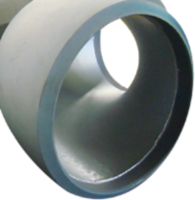

Conforma Clad™ Also Protects Your Fixed Equipment

- Radiant Return Bends for Delayed Coker Furnaces

- Outlet Elbows

- Thermowells

- VCM Oxychlorination Sparger Components

- General Conveyance

UltraFlex™ Radiant Return Bends for Delayed Coker Furnaces

Decoking operations, such as on-line spalling, can have a significant impact on the life of radiant return bends in delayed coker furnaces. UltraFlex technology delivers a Stellite™ 720 cladding designed to significantly reduce the risk of return bend wall thinning and rupture.

สอบถามเพิ่มเติมที่

บริษัท เพรสซิชั่น ทูลลิ่ง เซอร์วิส จำกัด

Tel. 02-3704900 auto 10 lines

Email : info@ptsc.co.th

Line : @ptsc